Circuit Design

Introduction

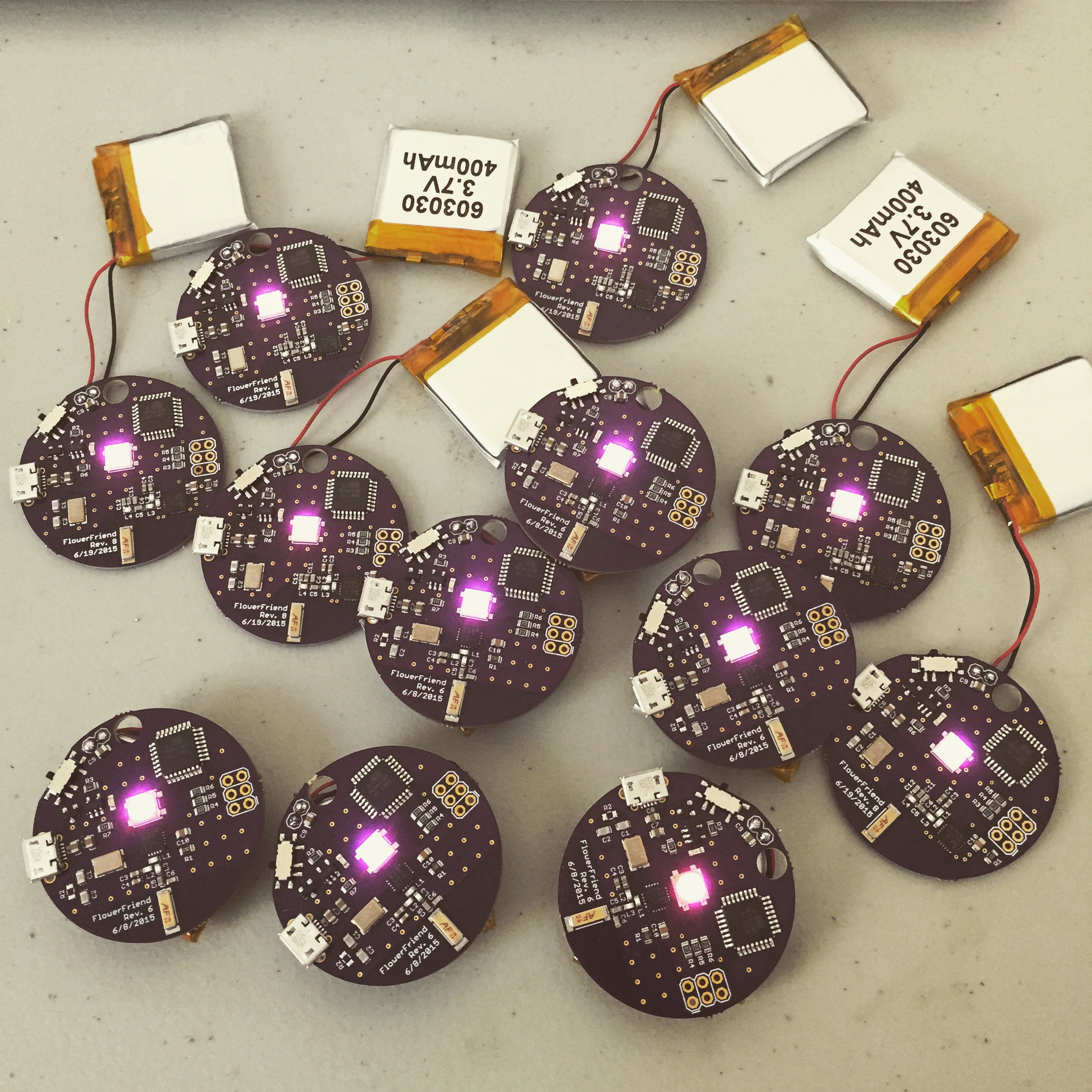

After some initial prototyping on breadboards with some simple Arduino code, the project quickly

became focused on designing and testing custom circuit boards (OSH Park, PCBCart), then figuring

out how to manufacture them efficiently and inexpensively. The main challenges were tuning the

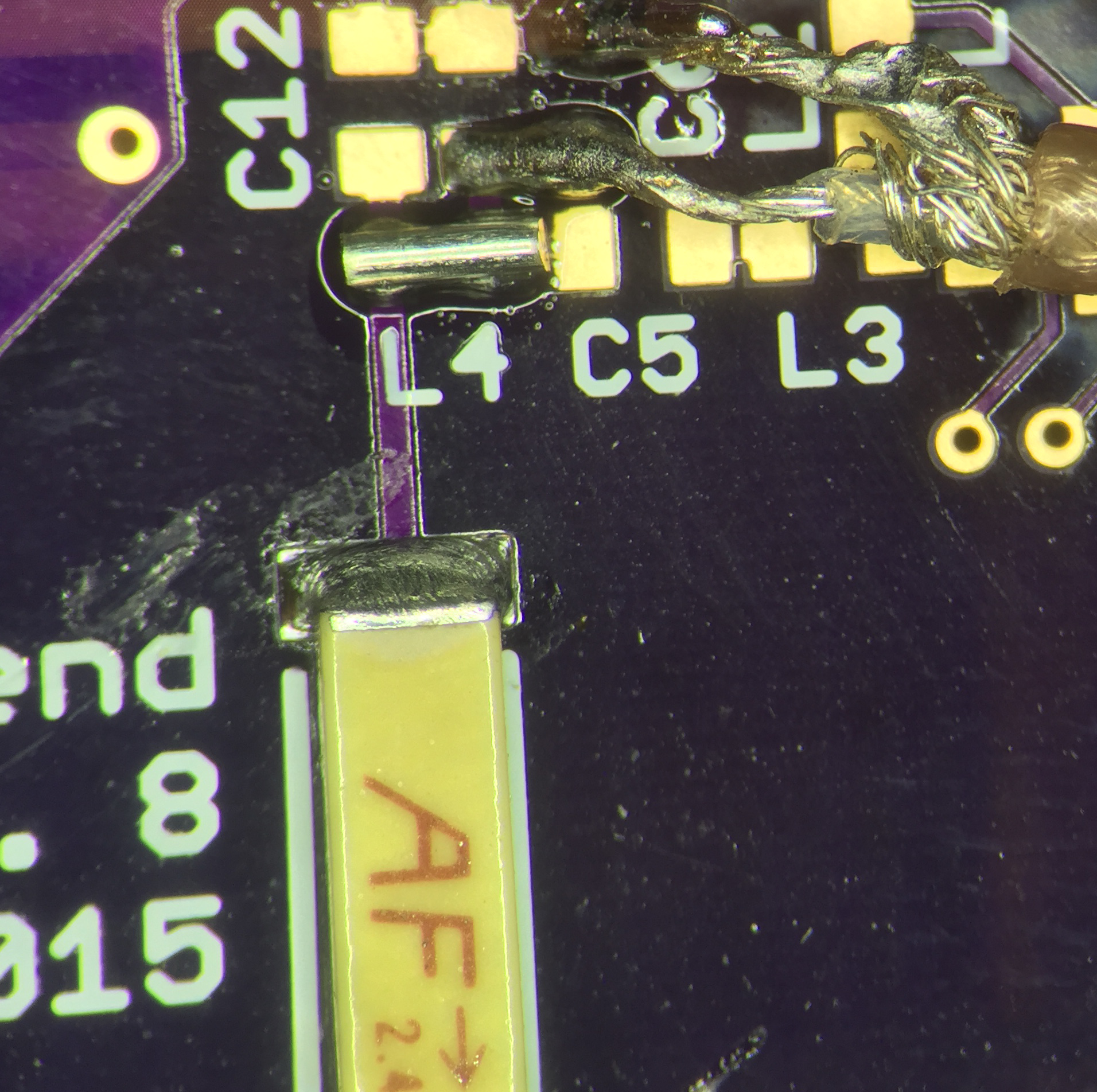

matching network of the NRF24L01+ to maximize range, and consistently hand-assembling the many

0603 sized components and NRF24L01+, which comes in a QFN (pinless) package. It is nearly

impossible to use an iron to solder a QFN package without damaging it. Instead, I used the solder

paste and stencil (OSH Stencils, Stencils Unlimited) method with baking in a toaster over (Reflowster).

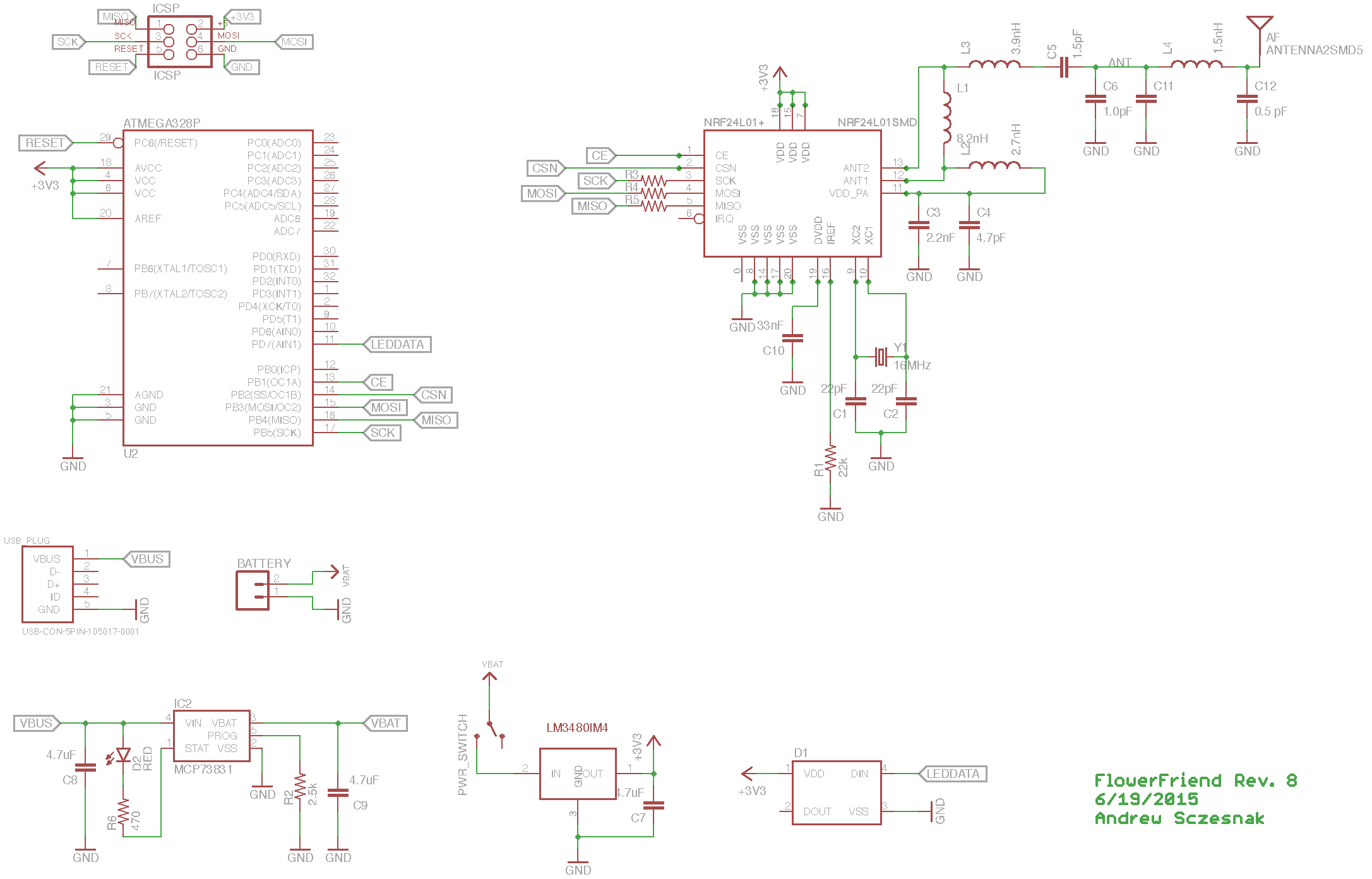

Design Overview

Every flower must have the ability to do calculations, transmit and receive RF signals, power a

color-changing LED, and recharge its battery over USB. To perform these functions, every flower

has these components:

- Atmel ATmega328P 8-bit microcontroller

- Nordic NRF24L01+ 2.4GHZ transceiver

- WS2812B "NeoPixel" SMD5050 RGB LED

- TI LM3480 3.3V Voltage Regulator

- MicroChip MCP73831 LiPo Charger

- Generic 400 mAh Lithium Polymer Battery

I went with the ATmega328P, NRF24L01+, and WS2812B because they are really common, are well supported with software and documentation, and I was already familar with them.

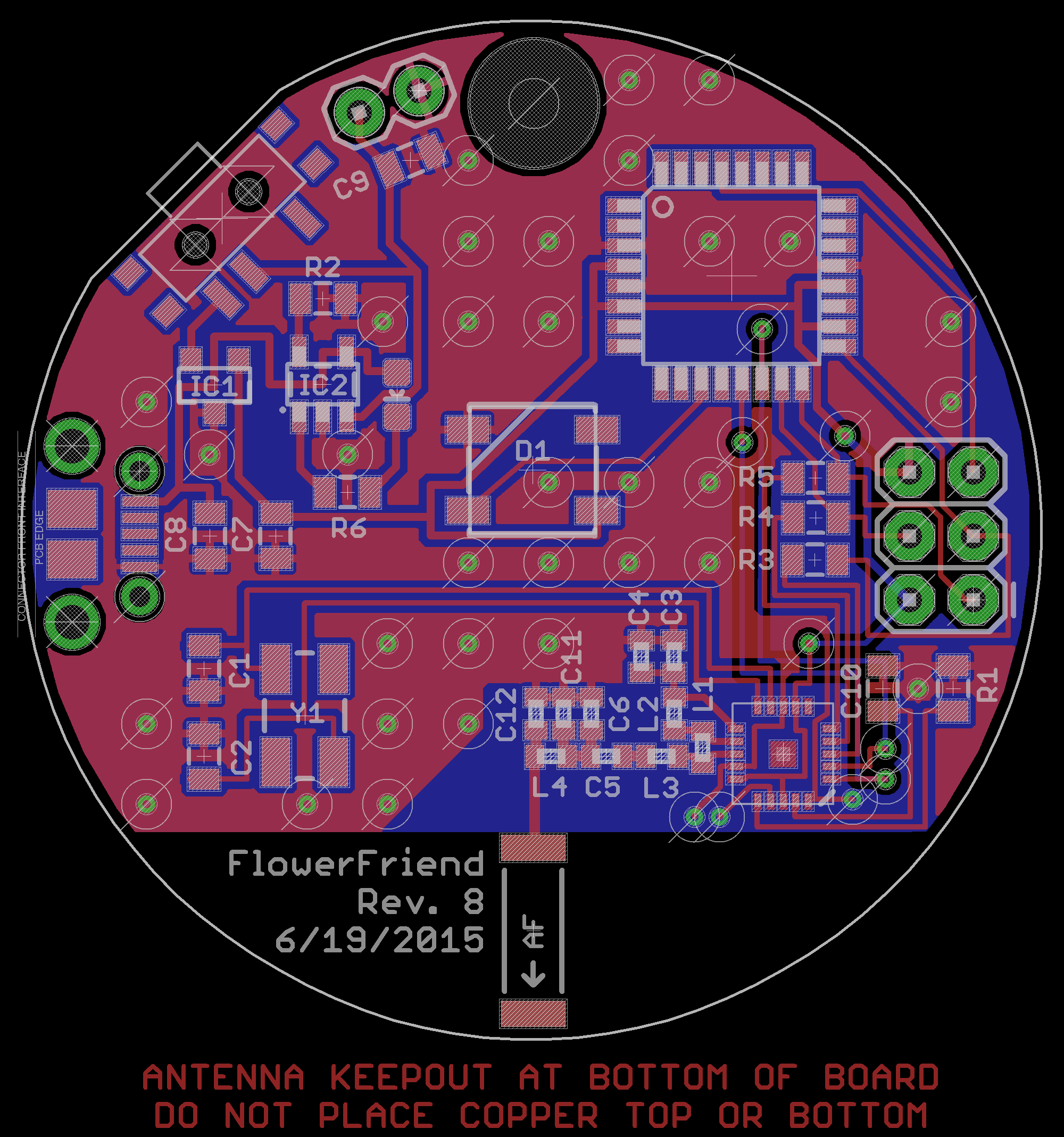

The boards were layed out into an approximately 4 cm circle in order to exactly fit a square 400 mAh battery on the back, and a glued-on fabric flower on the front.

Optimizing the NRF24L01+ Matching Network

Most of the design considerations came from rolling my own RF circuit rather than using an

FCC approved module ($$). Having never designed an RF board before, it quickly became

apparent that getting it to work up to spec was going to be a challenge. Initial prototypes

worked in the range of inches rather than the 150+ feet reported with commercial modules.

After a few non-working revisions and a productive discussion with a Nordic employee, I was

able to increase range to 150 feet, at night, with line-of-sight. This was accomplished by:

1) removing the top ground plane surrounding the RF front-end, 2) increasing the number of

vias connecting the top and bottom ground planes, and most importantly, 3) adding a few

components to bring the impedance of the matching network to the 50+0j ohms expected by the

chip antenna.

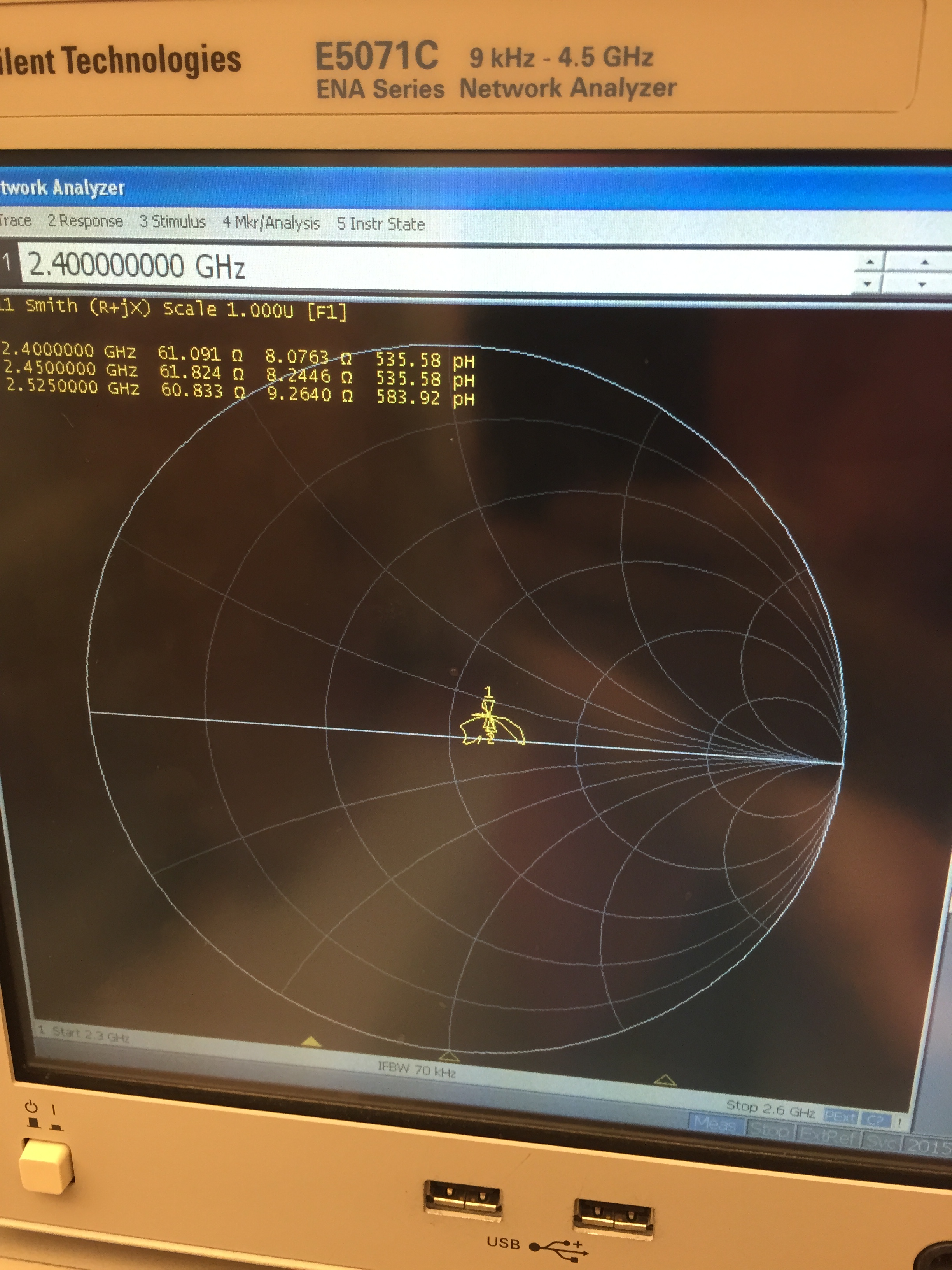

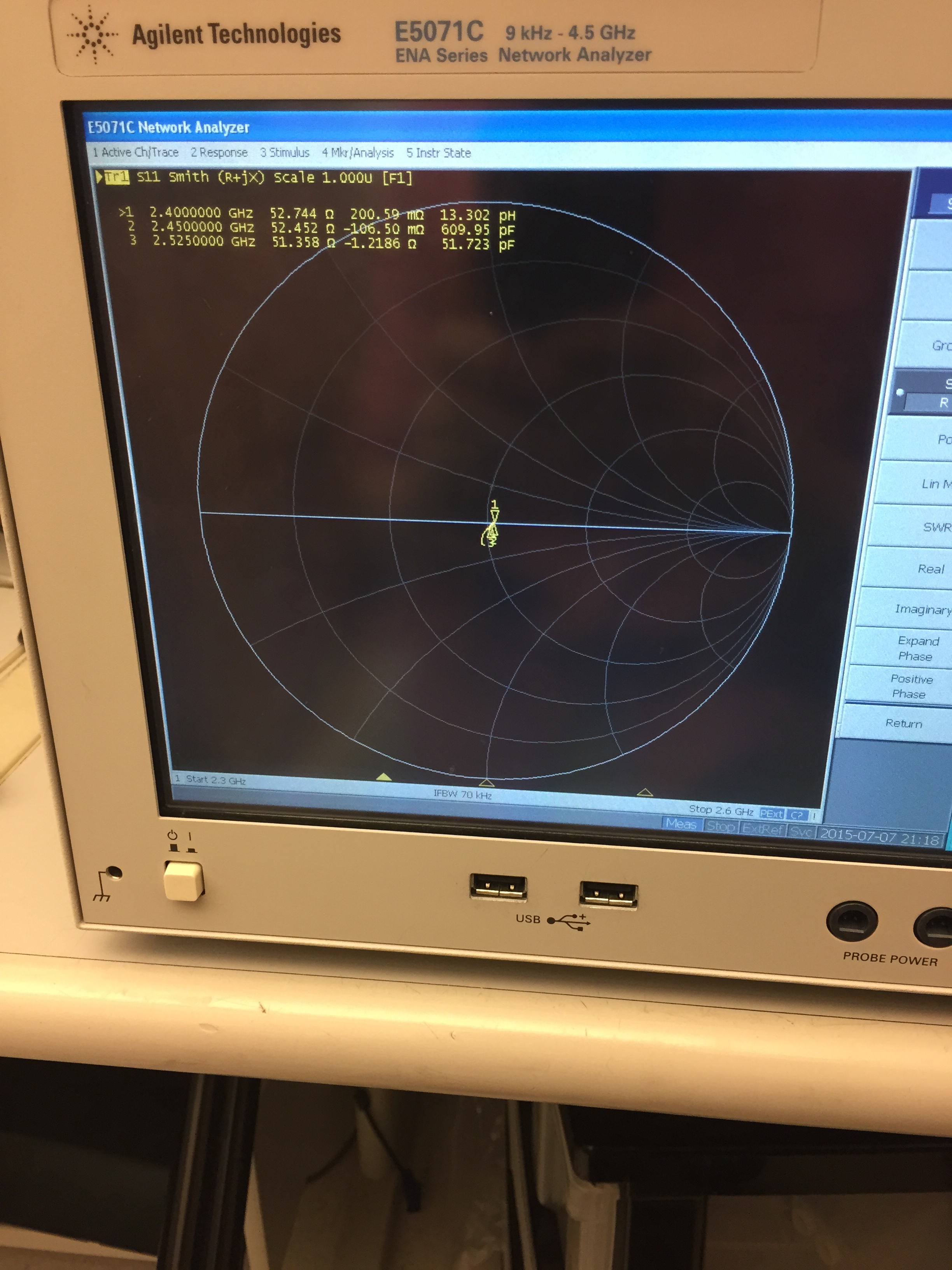

To optimize the matching network, you need access to a network analyzer. This fantastic

piece of equipment simultaneously generates signals across a frequency range, pumps them

through your DUT (device under test), and measures both the magnitude AND phase of the signal

either transmitted through the DUT (two-port measurement) or reflected back toward the

input (single-port measurement). It is important that the network analyzer can determine the

phase of the signal because this allows it to calculate the complex impedance of the matching

network. If the signal at 2.45 GHz output by the NRF24L01+ reaches the chip antenna at an

impedance other than 50 ohms, some amount of the signal is reflected back through the matching

network and is lost, resulting in a severe decrease in power output, and therefore, range.

After adding a series 1.5 nH inductor and shunt 0.5 pF capacitor, the impedance was pretty much

50+0j ohms, in spec for the 2.45 GHz chip antenna I used.

Reproducibly hand-assembling tiny components

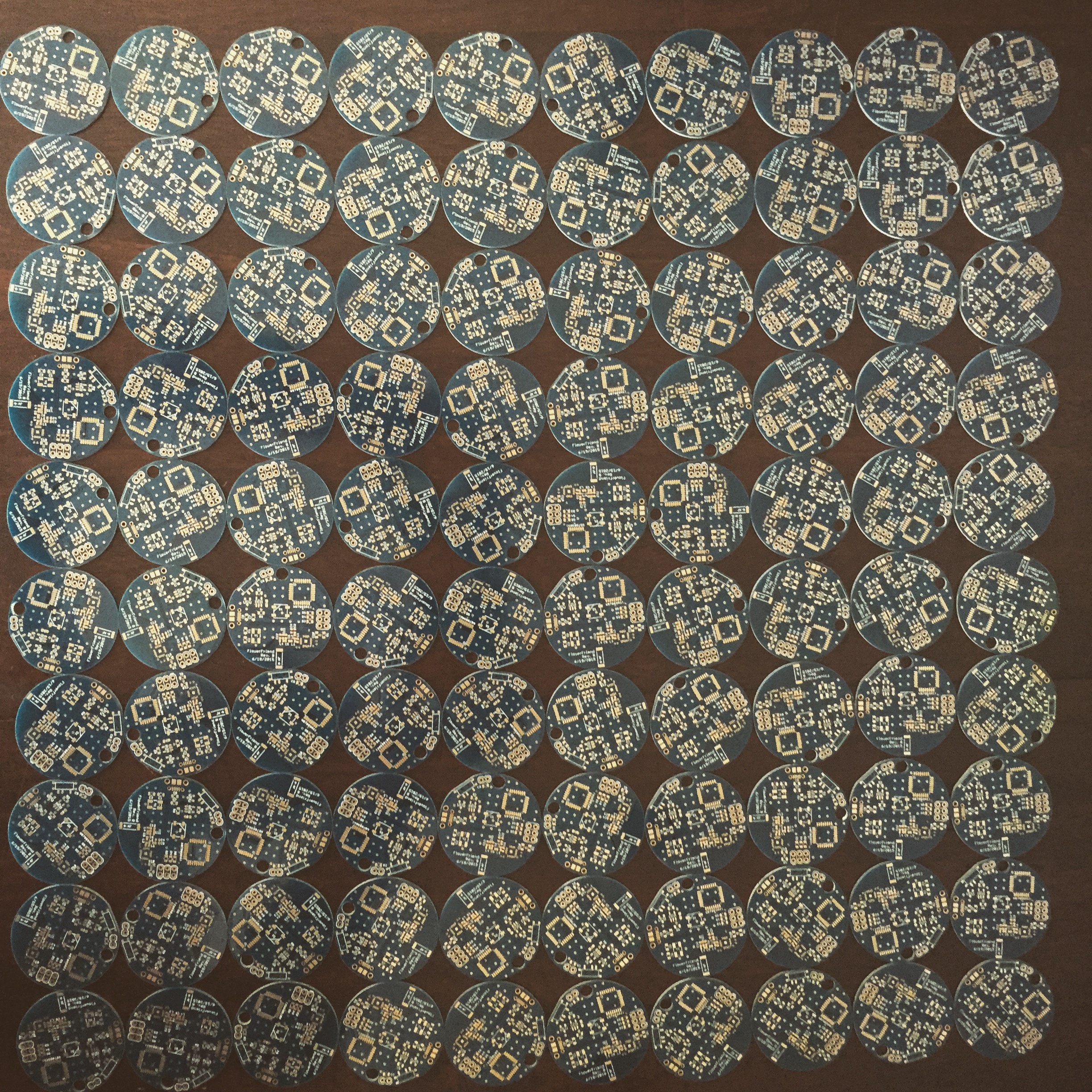

Once the design was finalized, I was faced with the daunting and tedious task of hand-assembling

100 units. Automated assembly was quoted at something like $5-10 per unit, which was just a little

too expensive.

In retrospect, it would have been worth it. It's just not reasonable to place thousands of these tiny surface mount components by hand and expect to have most of the units work. I wound up tossing around 35 of them due to shorts or crappy range (less than 70 feet). That said, it is possible to do pretty well by using a real, metal stencil, a good solder paste, and being careful. Getting the right amount of solder paste on the QFN package was the tricky part: too little and some pins weren't connected, too much and there were bridges that, if fixed with an iron, often ruined the chip.